Material Characteristics

Aluminium keeled boats offer exceptional strength-to-weight ratios, making them tough and able to absorb impacts that would damage fibreglass keeled boats. This is valuable when cruising in challenging environments where occasional bumps or scrapes are inevitable. Aluminium provides peace of mind, especially when traversing rocky or ice-strewn waters.1

However, aluminium boats are difficult to maintain paint-wise, as paint doesn't adhere well to the surface. Sailing with a stark, industrial look is one solution, but it's not to everyone's taste. Additionally, yard professionals often struggle with aluminium's unique properties, sometimes resulting in less-than-ideal repair jobs. Aluminium boats also come with steep price tags, making them a significant investment.

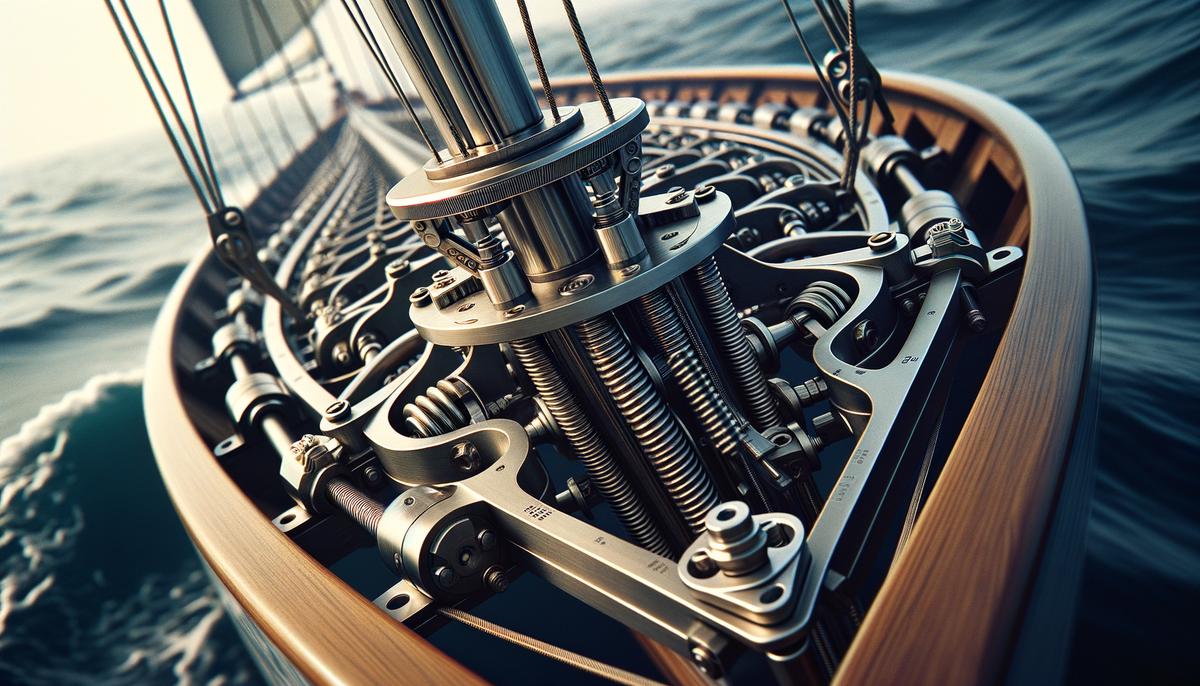

Swing keels offer versatility, allowing for shallow water exploration by pivoting up and reducing the boat's draught. This flexibility is perfect for accessing secluded anchorages. However, the internal mechanisms of a swing keel require regular maintenance, which can be challenging.

GRP (fibreglass) keeled boats are known for their resilience and ease of upkeep. Fibreglass doesn't corrode like aluminium and can bounce back from impacts, with most boatyards able to repair it easily.2 However, hidden faults in fibreglass can sometimes evade detection before purchase. Despite this, its widespread use and approachable nature make it a popular choice for part-time cruisers and those who prefer hassle-free yacht care.

Fixed keel boats, often made from fibreglass, have reliable, straightforward designs. A fixed keel provides stability and consistent performance in all sailing conditions. However, their deeper draughts make sailing in shallow waters more challenging.

In summary, aluminium keeled boats under 40ft offer robustness and adventure-readiness, but at a higher cost and with more demanding maintenance. Swing keels provide adaptability for shallow waters, while fixed keel GRP yachts deliver reliability and ease of care, appealing to those who prefer hassle-free sailing. Each material and design choice has its benefits and compromises, suiting different seafaring ambitions.

Keel Types and Performance

Fixed keels come in various designs, each with its own characteristics. The standard fin keel, favored by modern sailors, provides reliable stability, keeping the boat's motion smooth and predictable in choppy seas. Performance fin keels offer superior sailing edges through low weight and precise design.

Sailing a fixed keel yacht is a disciplined experience, offering grace and predictability in both steady seas and challenging gusts. However, fixed keels often require deeper waters, limiting exploration in shallow areas while ensuring unwavering stability on expansive voyages.

Swing keels are the versatile contortionists of the yachting world, adapting and retracting to various sailing conditions. They allow access to hidden coves and sheltered bays when waters grow shallow. However, this versatility introduces complexity, and regular maintenance is crucial to avoid issues.

In moderate or swelling seas, swing keels offer a good balance of dexterity and stability. In heavy winds or overly choppy conditions, their flexibility can occasionally feel like a compromise, not providing the same level of steadfastness as fixed keels.

Fixed keels excel in manoeuvrability, with their straightforward setup translating into more predictable handling, essential for sharp turns or swift tacks. Swing keels influence manoeuvrability in nuanced ways, allowing sailors to adjust their draught and find the optimal setup for tighter turns in calm waters or clever manoeuvring through busy marinas.

Fixed keels thrive on the open ocean, where depth is plentiful, and stability is crucial for lengthy passages. They demand respect for their deeper draft, avoiding shallow bays or narrow channels. Swing keels offer a balance, capable of venturing into more confined spaces while still performing well in broader, deeper areas when locked down.

Choosing a keel type is like selecting a loyal companion for a journey through unknown waters. Fixed keels promise consistent performance and unwavering support, while swing keels offer adaptability and the ability to explore various environments, though not without the need for attentive care. Each type has its own rhythm and character, allowing sailors to align their choices with either the comfort of predictability or the thrill of adaptable exploration.

Maintenance and Longevity

Maintaining an aluminium boat requires vigilance to guard against corrosion, especially galvanic corrosion. Despite aluminium's natural resistance to rust, it is susceptible to issues caused by dissimilar metals and stray electrical currents. Neglecting sacrificial anodes or improper handling by boatyard workers can lead to pitting. Once corrosion sets in, it can cause significant damage, requiring attentive and often costly repairs. Regular inspections and diligent maintenance are essential to prevent these issues.

Aluminium also presents challenges in terms of aesthetics. While it can endure impacts well, paint adherence remains a problem. Applying a fresh coat of paint on an aluminium hull can be persistent yet challenging, with paint often bubbling or peeling, necessitating routine touch-ups. Some sailors may choose to embrace the industrial, paint-free appearance for practicality.

GRP boats, known for their resilience, have their own maintenance quirks, most notably the potential for osmosis. Osmosis involves water ingress through the fibreglass, causing blisters and potentially compromising structural integrity. However, careful surveys and thorough antifoul treatments can often address these issues pre-emptively. The challenge lies in detecting osmosis, as it may not always be apparent during inspections, only revealing itself later on.

In terms of cost:

- Aluminium boats have a high initial outlay but can offset some expenses through their longevity and less frequent need for major structural repairs. The endurance of the material can justify the initial financial investment, provided the owner is diligent with maintenance.

- GRP boats, on the other hand, typically have more budget-friendly upfront costs but may accumulate maintenance costs over time as preventive measures against osmosis and wear-and-tear repairs are addressed.

Aluminium boats demand a knowledgeable owner, whether it's managing electrical systems to prevent galvanic corrosion or overseeing meticulous paint maintenance. The task list is substantial but manageable with dedication. GRP boats offer a more forgiving maintenance routine, with everyday upkeep like scrubbing decks and patching minor dings being relatively straightforward, making them a popular choice for sailors who prefer ease over expertise.

In terms of longevity, aluminium has an advantage against the elements. When properly cared for, an aluminium boat can serve generations of adventurers. Its sturdy nature means it doesn't suffer from the structural weakness that might affect improperly maintained fibreglass over decades. However, a well-maintained GRP boat can also achieve impressive lifespans, proving that, although it may require more frequent superficial repairs, its core strength endures.

Each material has its own unique maintenance requirements and longevity characteristics. Aluminium boats demand vigilance against corrosion and paint adherence issues, while GRP boats require attention to osmosis prevention and more frequent superficial repairs. Both materials can offer long-lasting performance when properly cared for, allowing sailors to choose the path that best aligns with their yachting priorities and maintenance preferences.

Cost Considerations

When contemplating the financial dimensions of acquiring an aluminium or GRP boat, one finds oneself amid a labyrinth of variables, each tugging at the purse strings in its unique manner.

Aluminium boats require a significant initial investment due to the specialised skills and materials needed for their construction. This hefty outlay, however, is mitigated by the boat's endurance and longevity, reducing the frequency of significant structural repairs over time.

GRP boats, on the other hand, offer more approachable initial costs due to the economies of scale in their production. However, these savings can gradually diminish as maintenance demands accrue. Long-term maintenance expenses for GRP boats often involve addressing issues such as osmosis and recurring blistering and water ingress, which can offset the initial savings.

Aluminium boats have the advantage of enhanced fuel efficiency and performance under sail, particularly beneficial over extended voyages, due to their lightweight build. However, this must be balanced against the cost of specialised maintenance and occasional professional interventions to address material-specific quirks.

GRP boats, with their ubiquitous presence and user-friendly maintenance characteristics, often translate to lesser operational costs. The widespread accessibility of services and parts at competitive prices contrasts with the sometimes niche and costly services required for aluminium, especially in regions where such expertise is scarce.

Regarding resale value, aluminium boats often command a higher price due to their enduring construction and ability to age gracefully. GRP boats, while typically experiencing more depreciation, still hold their value reasonably well, particularly those with a solid maintenance record and reputation for reliability.

Ultimately, the fiscal journey of aluminium versus GRP boats is a tale spun with threads of immediate expenditures juxtaposed against the long-term mosaic of maintenance and operational costs. Each path invites sailors to weigh their priorities and ambitions against their financial realities, aligning their choice with their dreams and economic horizons.

Suitability for Different Sailing Conditions

Understanding the suitability of aluminium and GRP boats with different keel types for diverse sailing conditions is crucial for sailors. Each combination of material and keel type influences the vessel's performance, stability, and overall reliability under different conditions.

For coastal cruising, GRP boats with fixed keels often shine due to their straightforward design and reliable handling in the calmer seas characteristic of coastal waters. The durability and ease of maintenance of GRP ensure that thrusts into rocky harbours or beach landings are manageable. Fin keels, fixed and integral to GRP boats, offer the needed balance and manoeuvrability for coastal explorations, while the shallower drafts of lifting or twin keels provide versatility in avoiding shoals and choosing anchorages.

Aluminium boats also offer a compelling option for coastal cruising, especially in regions with potential underwater hazards. Their strength-to-weight ratio and capacity to absorb minor collisions provide a buffer against inadvertent grazes and bumps. Swing keels on aluminium boats allow for retracting the keel in shallower waters without compromising structural integrity.

For offshore sailing, fixed keels, especially when complemented by aluminium hulls, assert their superiority1. The stability offered by these combinations translates to better handling in variable wind conditions and rougher seas. Aluminium's durability and lightweight augment sailing efficiency over extensive passages. GRP boats with fixed keels can also hold their own in offshore conditions, offering a balance of sturdiness and ease of maintenance.

In high-latitude expeditions, aluminium's virtues dominate. The material's impact resistance is a key asset when sailing icy waters, where the menace of calved ice chunks can wreak havoc on less resilient hulls. Swing keels add a layer of strategic manoeuvrability, enabling entry into shallower, safer anchorages whilst avoiding undue exposure to harsh elements. High-latitude GRP expedition vessels must be crafted with utmost precision and subjected to thorough safety checks, as they are relatively immune to cold climates but vulnerable to high-impact stresses.

The suitability of aluminium and GRP boats, intertwined with their chosen keel type, paints a vivid tableau of possibilities for different sailing conditions.

- Coastal cruising celebrates the accessibility and manageability of GRP along with the nimbleness of swing keels.

- Offshore sailing venerates the sturdy stability of fixed keels, favouring both trusted GRP and resilient aluminium.

- High-latitude ventures advocate for aluminium's unparalleled fortitude, reinforced by the adaptability of swing keels to sail treacherous, icy waters.

Ultimately, the choice between aluminium and GRP boats, along with their respective keel types, hinges on your specific needs and sailing conditions. Aluminium offers durability and resilience, while GRP provides ease of maintenance and cost-effectiveness. Your decision will shape your maritime adventures, ensuring you sail the waters with confidence and satisfaction.

Writio: Your AI content writer for high quality articles. This page was written by Writio.

Leave a Reply